Packaging innovation continues shaping how products are protected, presented, and perceived across competitive markets. Among flexible wrapping options, POF Shrink Film attracts attention for its ability to create smooth coverage while maintaining visual appeal. Businesses increasingly value materials that support reliable wrapping outcomes without adding unnecessary complexity to daily operations. This approach aligns with growing expectations for refined presentation combined with practical handling advantages.

Effective wrapping begins with controlled responsiveness. A well designed shrinkable surface adapts evenly when activated, allowing packaging to contour closely around items without creasing or surface stress. Such behavior enhances appearance while supporting orderly stacking during storage or movement. Clean conformity helps products retain structure throughout handling stages, reinforcing confidence across distribution channels.

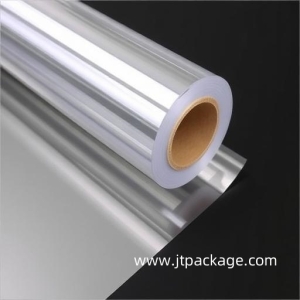

Visual clarity influences purchasing behavior more than ever. Transparent wrapping allows items to remain visible without distraction, supporting brand recognition through simplicity rather than excess decoration. Smooth surfaces reflect light evenly, giving packaged goods a polished look suitable for display focused environments. When packaging feels intentional, perceived value naturally increases.

Operational flow depends heavily on material consistency. Wrapping solutions that feed smoothly and seal reliably reduce interruptions during routine tasks. Predictable behavior allows teams to maintain steady pace without repeated adjustments. This reliability contributes to efficient workflows while supporting safe handling throughout production spaces.

Adaptability remains a defining advantage. Products vary widely in shape, texture, and grouping needs. Flexible wrapping materials accommodate these differences without sacrificing uniformity. Whether applied to individual items or bundled arrangements, adaptable films simplify packaging strategies while limiting material variety within operations.

Protection plays an equally important role. Tight wrapping minimizes exposure to dust, surface contact, and environmental influences during transit. Stable coverage helps prevent shifting while preserving alignment inside cartons or display units. Such stability supports consistent delivery conditions from origin to destination.

Sustainability awareness continues influencing material selection. Thoughtfully engineered films balance strength with reduced thickness, supporting responsible usage without compromising performance. Efficient material use aligns with broader goals related to waste reduction while maintaining dependable protection standards expected across modern supply chains.

Ease of handling benefits both operators and management. Materials that unwind smoothly and respond predictably reduce fatigue while improving overall safety. Simplified application supports consistent outcomes across shifts, helping teams maintain quality without extensive retraining or oversight.

Long term value emerges through reliability. Packaging that performs consistently limits rework, reduces material loss, and supports brand integrity. When wrapping delivers dependable results across varied conditions, organizations gain confidence in both presentation and operational planning.

Selecting a trusted supplier remains essential. Brands benefit from partners committed to refinement, support, and adaptability. In this context, JTPACKAGE represents a dependable presence focused on packaging solutions that align functionality with presentation expectations across diverse markets.

For further background regarding material characteristics and practical usage, additional information is available through the following reference https://www.jtpackage.com/news/industry-news/pof-shrink-film-all-you-need-to-know-features-uses-and-more.html