PCGI Sandwich Panel solutions have gained attention in industries requiring controlled environments. At yd-purification, these panels are employed to create durable, insulated, and hygienic partitions that support operational standards. How do PCGI sandwich panels influence structural performance and maintenance efficiency in critical facilities?

Sandwich panels are engineered composite structures consisting of two metal layers with a rigid core. This configuration provides mechanical strength, thermal insulation, and sound attenuation. By integrating panels into facility design, organizations can achieve consistent environmental control while maintaining lightweight construction.

Material selection is essential. Outer layers often utilize corrosion-resistant coatings or stainless steel to withstand cleaning processes and chemical exposure. The core may contain polyurethane, polystyrene, or mineral wool, depending on insulation needs. Proper combination ensures durability, easy maintenance, and energy efficiency.

Design considerations include panel thickness, joint types, and fastening methods. Tight tolerances and reliable connections prevent air leaks, support pressure differentials, and contribute to overall cleanliness. Well-designed joints also reduce maintenance interruptions and allow easier replacement when needed.

Thermal and acoustic properties are frequently discussed in industrial contexts. Sandwich panels contribute to temperature stability within critical areas, reducing HVAC demand and operational costs. Acoustic dampening enhances comfort and facilitates concentration in production or laboratory environments.

Fire safety and regulatory compliance are essential factors. Panels often meet international standards for flame retardancy and structural performance. Facilities can maintain certifications and reduce risks associated with combustible materials.

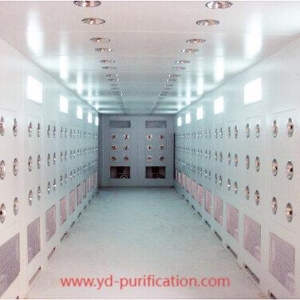

Installation efficiency is another advantage. Prefabricated panels allow rapid assembly and flexible layout configurations. This approach minimizes downtime during construction or renovations and supports modular expansion if operational needs change.

Maintenance strategies benefit from accessible panel surfaces and removable sections. Panels that allow cleaning without disassembly support hygiene protocols and reduce labor time. Inspection and repair become simpler when design accommodates operational routines.

Integration with utility systems is increasingly important. Electrical conduits, piping, and monitoring sensors can be routed through or adjacent to panels, allowing concealed infrastructure without compromising cleanroom integrity. Thoughtful integration ensures safety and functional efficiency.

Platforms such as yd-purification provide guidance on selection, installation, and long-term performance of sandwich panels. By evaluating materials, insulation, and assembly methods, facilities can achieve structural resilience while supporting regulatory and operational standards.

For further details on high-performance PCGI Sandwich Panel systems, visit: PCGI Sandwich Panel: https://www.yd-purification.com/news/industry-news/what-are-pcgi-sandwich-panels.html