In modern electrical manufacturing, efficiency, precision, and consistency are key factors that determine product quality. As demand grows for reliable electrical components such as junction boxes, manufacturers are turning to advanced automation solutions to ensure accuracy and cleanliness in the production process. One of the most important innovations driving this transformation is the Junction Box Glue Filling Machine.

As a trusted equipment manufacturer, Bluemann is committed to providing intelligent production solutions that enhance product reliability and operational efficiency. The Bluemann Junction Box Glue Filling Machine combines precision control, double-head glue filling, and anti-drip technology to deliver exceptional results in electrical assembly and sealing applications.

The Role of Glue Filling in Junction Box Manufacturing

A junction box serves as a vital component in electrical systems, protecting wire connections from dust, moisture, and mechanical damage. To ensure long-term durability and safety, proper sealing with adhesive or potting material is essential.

Traditional manual glue filling methods often lead to inconsistencies—such as uneven application, glue leakage, and contamination of internal components. These issues can compromise the box’s waterproof and dustproof performance, resulting in product failures or maintenance problems later.

To address these challenges, automated glue filling machines have become the preferred choice for manufacturers seeking to optimize quality, reduce waste, and achieve stable production outcomes.

Introducing the Bluemann Junction Box Glue Filling Machine

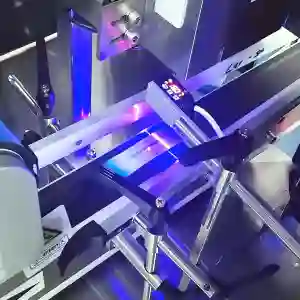

The Bluemann Junction Box Glue Filling Machine is a cutting-edge automation system designed specifically for precision glue dispensing in electrical component assembly. Engineered with double-head glue filling technology, it significantly improves production efficiency while maintaining strict quality control.

The machine’s dual dispensing heads allow simultaneous glue application on two points or components, reducing cycle time and ensuring a uniform adhesive distribution. This is particularly beneficial in large-scale production lines where speed and consistency are crucial.

In addition, the system is equipped with a drip-proof hopper, which prevents glue from dripping onto sensitive electrical components—eliminating contamination risks and material waste. The result is a cleaner, safer, and more efficient production process.

Key Features and Advantages

1. Double-Head Glue Filling for Higher Efficiency

The dual-head design doubles output without compromising accuracy. Each dispensing head operates independently, allowing for flexible control of glue volume and speed. This ensures precise application across different junction box models, enhancing production efficiency and reducing labor costs.

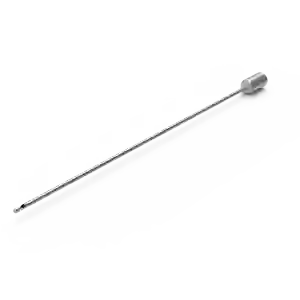

2. Drip-Proof Hopper Design

A common challenge in glue filling is the risk of adhesive dripping when the dispenser is idle. Bluemann solves this issue through an intelligently designed drip-proof hopper that automatically seals the outlet, preventing glue leakage and contamination of components. This design maintains a clean workspace and minimizes material loss.

3. Precision Control and Stable Performance

Equipped with advanced servo control systems, the Junction Box Glue Filling Machine delivers consistent dispensing accuracy. Glue flow rate, pressure, and volume can be precisely adjusted to meet various adhesive requirements, ensuring uniform sealing results across all products.

4. User-Friendly Operation

The machine features a touchscreen interface that allows easy parameter setup, operation monitoring, and fault diagnosis. Operators can quickly switch between production modes, improving flexibility and reducing downtime.

5. Easy Maintenance and Durability

Built with high-quality stainless steel and corrosion-resistant materials, the Bluemann machine is designed for long-term durability. Its modular design allows for simple maintenance, reducing operational costs and enhancing reliability over time.

How Automation Improves Product Quality

The introduction of automated glue filling systems marks a major advancement in the quality control of junction box manufacturing. By minimizing manual errors and standardizing adhesive application, Bluemann Junction Box Glue Filling Machines contribute to several critical improvements:

-

Enhanced Product Consistency: Automation ensures each junction box receives the same precise amount of glue, achieving uniform sealing and waterproofing quality.

-

Reduced Contamination Risk: The drip-proof design prevents unwanted glue spills that could damage components or cause performance issues.

-

Improved Adhesion and Sealing Strength: Accurate dispensing promotes better bonding between surfaces, improving long-term reliability in harsh environments.

-

Optimized Production Efficiency: With double-head filling, manufacturers can meet large production demands while maintaining top-tier quality standards.

These benefits make automated glue filling an essential component of modern electrical equipment manufacturing, where precision and performance are non-negotiable.

The Future of Smart Manufacturing in Electrical Assembly

As smart manufacturing continues to evolve, automation will remain a driving force behind production efficiency and product quality improvement. The Junction Box Glue Filling Machine exemplifies how advanced equipment can transform traditional manufacturing processes into intelligent, data-driven systems.

With innovations like Bluemann’s dual-head glue filling technology and drip-proof design, manufacturers can achieve seamless integration between precision, speed, and cleanliness—ensuring that every junction box leaving the production line meets the highest industry standards.

Conclusion

The Junction Box Glue Filling Machine is more than just a piece of equipment—it’s a crucial part of modern, intelligent manufacturing. By combining double-head glue filling, precision control, and drip-proof technology, Bluemann delivers a solution that improves product quality, boosts efficiency, and enhances long-term reliability.

As electrical systems become more complex and quality expectations rise, Bluemann’s automation solutions continue to lead the way in building smarter, cleaner, and more efficient production environments.

For more product details, please see:

Junction Box Glue Filling Machine – Bluemann

https://www.bluemannsolar.com/how-junction-box-glue-filling-machines-improve-product-quality.html