In modern laboratories, efficiency, precision, and reproducibility are critical. Whether working in biotechnology, pharmaceuticals, environmental science, or food research, sample preparation plays a crucial role in determining the success of experimental outcomes. Among the tools designed to enhance this process, ultrasonic homogenizers stand out for their versatility and effectiveness.

What is an Ultrasonic Homogenizer?

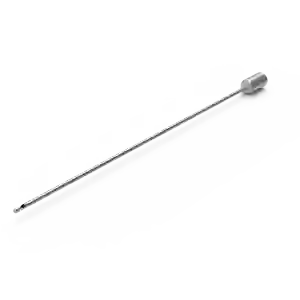

An ultrasonic homogenizer, also known as a sonicator, is a device that uses high-frequency ultrasonic waves to break down particles in a liquid medium. It works by converting electrical energy into mechanical vibrations through a transducer. These vibrations generate cavitation bubbles in the sample, which collapse violently, creating intense shear forces that break apart cells, disperse particles, and mix solutions thoroughly.

This process is ideal for tasks like cell lysis, nanoparticle dispersion, emulsification, and homogenization of biological or chemical samples.

Key Advantages of Ultrasonic Homogenizers

1. Efficient Cell Disruption

Ultrasonic homogenizers offer rapid and effective cell lysis, making them ideal for extracting proteins, DNA, RNA, and other cellular contents. Unlike chemical lysis, sonication avoids the use of potentially interfering reagents, providing purer extracts for downstream applications.

This is especially useful in molecular biology, genomics, and proteomics research.

2. High Reproducibility

Because ultrasonic homogenizers allow for precise control of amplitude, time, and duty cycle, they ensure consistent results from batch to batch. This is a major advantage in laboratories where standardization and repeatability are crucial, such as in pharmaceutical testing or quality control environments.

3. Wide Range of Applications

Ultrasonic homogenizers are used in various scientific and industrial fields, including:

Life sciences – Cell disruption, DNA shearing, enzyme extraction

Pharmaceuticals – Nanoemulsion preparation, drug formulation

Food & Beverage – Flavor extraction, emulsification of ingredients

Environmental testing – Soil and sludge sample processing

Cosmetics – Homogenizing creams and lotions

Their adaptability makes them a cost-effective and space-saving tool for multi-purpose laboratories.

4. Superior Particle Size Reduction

Ultrasonic homogenization can achieve nanoscale particle size reduction, often better than mechanical or chemical methods. This is critical in the production of stable suspensions, emulsions, and nanoparticles, where surface area and uniformity affect performance and stability.

5. Minimal Sample Contamination

Unlike mechanical homogenizers that use rotating blades or grinders, ultrasonic homogenizers have fewer moving parts, reducing the risk of sample contamination. The probe (or horn) is typically made from titanium, which is chemically inert and easy to clean, making it safe for sensitive biological or pharmaceutical samples.

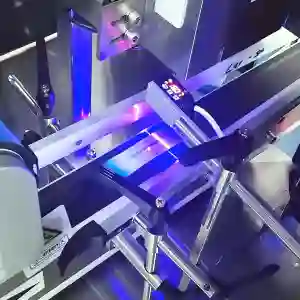

6. Customizable and Scalable

From bench-top laboratory models for small volumes (e.g., 0.2–500 mL) to industrial-scale systems for liters of material, ultrasonic homogenizers are scalable to meet different production needs. Many models offer programmable settings and automation options, supporting complex research protocols or large-volume production lines.

7. Energy Efficiency and Cost Savings

Compared to other particle reduction or mixing methods, ultrasonic homogenization is energy-efficient and often faster, helping to reduce operational time and labor costs. With fewer consumables and maintenance requirements, it can also lower long-term operating expenses.

Why Switch to an Ultrasonic Homogenizer?

Laboratories that require precision sample processing, especially when dealing with sensitive biological or nano-scale materials, find ultrasonic homogenizers to be a valuable upgrade. Their non-thermal, non-chemical approach preserves sample integrity while maximizing extraction or dispersion results.

Moreover, the compact design, low maintenance needs, and versatility of ultrasonic homogenizers make them suitable for both academic research and industrial R&D labs.

Final Thoughts

As the demand for advanced laboratory solutions grows, ultrasonic homogenizers offer a modern alternative to traditional mixing, grinding, and dispersing techniques. Their ability to deliver faster, cleaner, and more consistent results makes them a smart investment for any lab looking to enhance its sample preparation capabilities.

If you're considering upgrading your lab equipment, explore our range of ultrasonic homogenizers designed for both research and production-scale needs. With customizable options and expert support, we help you unlock the full potential of ultrasonics in your lab.

https://www.zinscien.com/explore-the-advantages-of-ultrasonic-homogenizers-in-the-laboratory.html