In today’s industrial landscape, the demand for precision, reliability, and durability in metal components has never been higher. From automotive manufacturing to electrical systems and marine applications, every sector relies on components that can perform under extreme conditions. Die-casting anode parts play a vital role in achieving this balance of strength, precision, and conductivity. At Aoke, we specialize in the design and manufacturing of advanced die-casting anode parts that set new standards for performance, corrosion resistance, and long-term stability.

1. Understanding Die-Casting Anode Parts and Their Industrial Importance

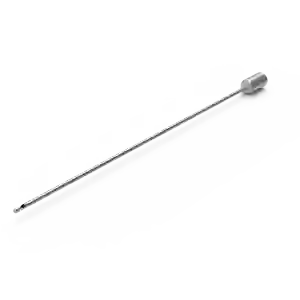

Die-casting anode parts are engineered metal components produced through high-pressure die-casting — a process that forces molten metal into precision molds to create complex, dimensionally accurate parts. These components are widely used in electrochemical and galvanic applications, where efficient current transfer and resistance to corrosion are essential.

Aoke’s expertise lies in producing anode parts that ensure consistent electrical conductivity while maintaining structural integrity. Whether used in electroplating equipment, water treatment systems, or marine cathodic protection setups, these parts are designed for peak efficiency and longevity.

2. The Aoke Advantage: Advanced Manufacturing for Superior Quality

What sets Aoke apart in the field of die-casting is our unwavering commitment to engineering excellence and material precision. Our die-casting process integrates:

-

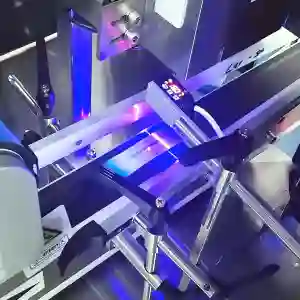

High-Pressure Die-Casting Technology: Ensures consistent part density, minimal porosity, and excellent dimensional stability.

-

Premium Metal Alloys: Aoke uses corrosion-resistant materials such as aluminum, zinc, and magnesium alloys, optimized for specific electrochemical conditions.

-

Surface Finishing Precision: Advanced machining and coating technologies provide smooth surfaces that improve conductivity and resist wear.

-

Automated Quality Inspection: Every die-cast anode part undergoes strict dimensional and metallurgical analysis to meet international performance standards.

This combination of material science and precision manufacturing enables Aoke’s die-casting anode parts to deliver exceptional performance in even the most demanding environments.

3. Key Features and Performance Benefits

Aoke’s die-casting anode parts are not just functional — they are engineered solutions that improve overall system performance. Key benefits include:

-

High Electrical Conductivity: Ensures efficient current flow for stable electrochemical reactions.

-

Excellent Corrosion Resistance: Withstands exposure to moisture, salt, and harsh industrial chemicals.

-

Enhanced Mechanical Strength: Maintains structural integrity under thermal and mechanical stress.

-

Precision Fit and Uniformity: Guarantees seamless integration into complex assemblies and systems.

-

Extended Service Life: Reduces maintenance requirements and long-term operational costs.

By focusing on these attributes, Aoke ensures that every component performs consistently across diverse applications — from energy systems to heavy machinery.

4. Applications Across Diverse Industries

The versatility of die-casting anode parts makes them indispensable across numerous industrial sectors. Aoke’s components are designed for:

-

Marine Engineering: Providing corrosion protection for ships, offshore platforms, and underwater pipelines.

-

Automotive and Transportation: Used in electrical and structural assemblies requiring lightweight strength.

-

Electrochemical Processes: Supporting anode and cathode systems in plating and electrolysis applications.

-

Power and Energy Systems: Enhancing electrical distribution efficiency in renewable and conventional energy setups.

-

Aerospace Manufacturing: Delivering high-performance, corrosion-resistant components for sensitive flight systems.

Each application demands a unique balance of conductivity, stability, and precision — something Aoke consistently achieves through tailored material selection and process optimization.

5. Aoke’s Commitment to Sustainability and Innovation

As industries evolve toward greener and more efficient technologies, Aoke leads the way in sustainable metal processing. Our die-casting operations emphasize:

-

Eco-Friendly Alloy Development: Reducing waste and emissions through recyclable materials.

-

Energy-Efficient Casting Processes: Optimizing production cycles for minimal environmental impact.

-

Lifecycle Optimization: Designing parts for longer operational lifespans, reducing replacement frequency and resource use.

Sustainability is not an afterthought at Aoke — it is embedded in every stage of our product development.

6. Why Choose Aoke for Die-Casting Anode Parts

Partnering with Aoke means choosing reliability, precision, and innovation. Our engineering teams collaborate closely with clients to provide:

-

Custom Design Solutions tailored to specific application needs.

-

Comprehensive Technical Support from concept to production.

-

Global Quality Assurance certified to ISO and international industry standards.

By combining deep expertise with cutting-edge technology, Aoke continues to set benchmarks in the die-casting industry — delivering products that drive performance, reduce costs, and support long-term operational excellence.

Conclusion

In a world that demands both performance and sustainability, Aoke’s die-casting anode parts represent the next generation of industrial component design. Through advanced metallurgy, precision engineering, and a commitment to innovation, Aoke helps industries operate more efficiently and sustainably.

From marine protection systems to high-tech manufacturing environments, our die-casting anode parts deliver what every industry needs most — consistent performance, superior quality, and enduring reliability.

https://www.aoprecision.com/how-die-casting-anode-parts-elevate-industrial-efficiency.html