In modern manufacturing and machining operations, precision, durability, and efficiency are non-negotiable. Choosing the right cutting tools can drastically impact productivity, product quality, and overall operational cost. Wholesale tungsten carbide cutting tools offer a reliable solution for industries requiring high-performance machining at competitive prices. HAOCHENG, a leading manufacturer and supplier, specializes in producing premium tungsten carbide cutting tools that combine precision, longevity, and versatility for a variety of industrial applications.

What Are Tungsten Carbide Cutting Tools

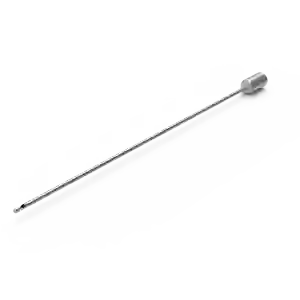

Tungsten carbide cutting tools are industrial-grade tools made from a composite of tungsten carbide and cobalt. They are renowned for their hardness, wear resistance, and high-temperature tolerance, making them ideal for cutting, shaping, and machining metals, composites, and other hard materials.

Unlike traditional steel tools, tungsten carbide cutting tools maintain their sharpness over extended usage, allowing manufacturers to operate at higher speeds and with greater accuracy, reducing downtime and production errors.

Why Buying Wholesale Tungsten Carbide Cutting Tools Matters

Purchasing wholesale tungsten carbide cutting tools offers several advantages for businesses of all sizes:

1. Cost Efficiency

Buying in bulk reduces the cost per unit, making it more economical for manufacturers who need multiple tools for large-scale operations. HAOCHENG’s wholesale program ensures that high-quality tools are accessible at competitive prices without compromising on performance.

2. Consistent Quality

Using tools with variable quality can lead to inconsistent machining results. HAOCHENG’s tungsten carbide cutting tools are manufactured under strict quality control, providing uniform hardness, precision, and performance for every batch.

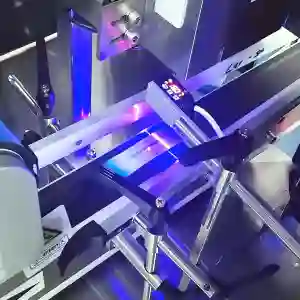

3. Increased Productivity

Tungsten carbide’s superior wear resistance allows for longer tool life and less frequent replacements. Operators can maintain continuous machining with fewer interruptions, maximizing overall efficiency.

4. Versatility Across Applications

HAOCHENG’s tungsten carbide cutting tools are suitable for a wide range of industrial applications:

-

Metalworking: Cutting, milling, and shaping steel, aluminum, and alloys.

-

Woodworking: Precision carving and shaping of hardwoods.

-

Plastic and composites: High-speed machining without tool degradation.

-

Automotive and aerospace: Components requiring high accuracy and smooth finishes.

5. Enhanced Safety and Reliability

High-quality tools reduce the risk of tool breakage, which can damage workpieces or pose safety hazards. HAOCHENG’s cutting tools are engineered for mechanical stability, ensuring safe operation even under high-speed or high-stress conditions.

Key Features of HAOCHENG Wholesale Tungsten Carbide Cutting Tools

-

Exceptional Hardness: Maintains cutting edge longer than standard steel tools.

-

High Wear Resistance: Reduces frequent replacements and downtime.

-

Temperature Tolerance: Handles high-speed machining without deformation.

-

Precision Manufacturing: Ensures tight tolerances for accurate cuts.

-

Wide Range of Tool Types: Includes end mills, drills, inserts, reamers, and more.

HAOCHENG’s commitment to precision engineering guarantees that every tool meets industrial standards, delivering reliable performance for demanding production environments.

How to Choose the Right Tungsten Carbide Cutting Tool

Selecting the appropriate tungsten carbide cutting tool depends on several factors:

-

Material to Be Machined: Harder materials require higher-grade carbide with specific grain structures.

-

Cutting Speed and Feed Rate: Tools must withstand the operational parameters of your machines.

-

Tool Geometry: Proper shape, angles, and coating improve cutting efficiency.

-

Production Volume: High-volume operations benefit more from durable, long-lasting tools.

-

Supplier Reliability: Partnering with a reputable manufacturer like HAOCHENG ensures consistent quality and technical support.

By considering these factors, manufacturers can optimize tool performance, reduce costs, and improve machining outcomes.

Why Choose HAOCHENG

As a trusted provider of wholesale tungsten carbide cutting tools, HAOCHENG combines technical expertise, precision engineering, and customer-focused service. Key benefits include:

-

Consistent Product Quality: Every tool undergoes rigorous quality control.

-

Custom Solutions: Tailored tools to match specific machining requirements.

-

Technical Support: Expert guidance on tool selection, usage, and maintenance.

-

Global Distribution: Reliable supply chain ensuring timely delivery of bulk orders.

Partnering with HAOCHENG ensures manufacturers gain access to high-performance tools, reducing downtime and maximizing production efficiency.

Conclusion

Maximizing productivity and precision in machining operations requires the right tools. Wholesale tungsten carbide cutting tools from HAOCHENG deliver durability, accuracy, and efficiency, helping businesses reduce costs, improve output, and maintain product quality. By investing in high-quality tungsten carbide tools in bulk, manufacturers can stay competitive in demanding industries while ensuring long-term operational reliability. To learn more about their product line, visit Tungsten Carbide Cutting Tool.